We spend a lot of time boasting about the long list of benefits that come with adding crickets to our diet. However, we don't really discuss where the crickets we use come from and how they are farmed. For that reason, we have decided to dedicate this entire blog post to cricket farming!

The farm

The cricketswe use in all our products are raised in North America's largest cricket farm (Entomo Farms), which is located in Norwood, Ontario. The farm has 60 000 square feet of production space, and it includes 2 barns and 1 processing facility. The barns in which the crickets are raised are renovated abandoned chicken barns, and can hold roughly 100 million crickets at any given time. The barns are home to crickets from all stages of maturation i.e. from the egg to the mature adult ready for harvest.

The different stages of cricket farming

1. The eggs

Did you know that a cricket can lay over 100 eggs during it's short life cycle? With that being said, it is no surprise that cricket eggs are laid every single day on a cricket farm. Once eggs are laid, they are quickly moved to the incubator room. In the warm incubator room, there are lots of tubs filled with dirt, cricket eggs, and egg cartons, and there can be as many as hundreds of thousands of eggs in every tub! After 10-12 days of incubation, the eggs finally hatch. Nymphs are then born and they begin to climb onto the egg cartons. It is at that moment that they are taken to the nursery room.

2. The nymphs

The nymphs stay in the nursery room for 2 weeks. The nymphs look like small versions of adult crickets, however they are not fully developed yet. During this stage of their lifecycle, the nymphs grow and shed their exoskeleton a few times and eventually develop into adult crickets.

3. The adults

Once the nymph become adult crickets, they are moved to the production rooms, where they are grown for another 4 weeks before harvesting, which occurs at the end of their natural life cycle. These rooms have rows of cardboard partitions known as "cricket condos", and there is food and water in every row.

Unlike most cricket farms where the insects live in plastic cages, the crickets from this farm are raised "free-range". They can hop from feed station to feed station and burrow deep in the vertical cardboard partitions whenever they chose to.

The processing room

Once crickets are harvested by collection from their cricket condos, they are moved to the processing facility where they are rinsed, put to sleep, roasted, and ground up into a powder. 100% of the cricket is used in this process, meaning there is no waste!

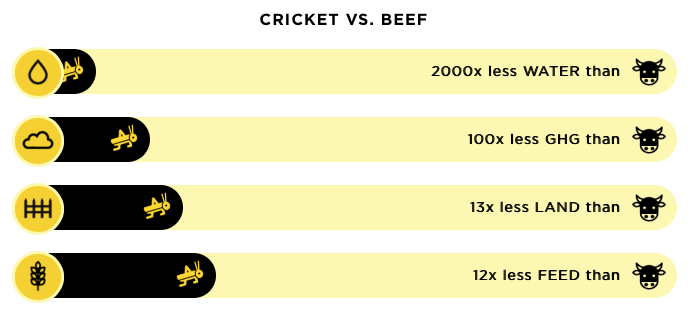

Cricket farming VS beef farming

To put everything in perspective, lets compare cricket farming with beef farming.As mentioned above, crickets are bred invery large numbers in a barn, and in less than 6 weeks they become adults. For instance, Entomo Farms uses a 60,000 square foot building hosting about 100 million crickets at a time. In terms of their diet, they need small quantities of food and water. On the other hand, beef require lots ofwater, lots offood, lots of space, and lots oftime to raise.

In fact, cricket production requires 12 times less feed, 2000 times les water, 13 times les land, and produces 100 times less greenhouse gases, making it a much more eco-friendly option.

Cricket is the new superfood ! Why don't you try cricket products? Order here!

Leave a comment (all fields required)